- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Choose the Best Cargo Tarpaulin for Maximum Protection and Durability

How to Choose the Best Cargo Tarpaulin for Maximum Protection and Durability

Understanding Tarpaulins and Their Importance

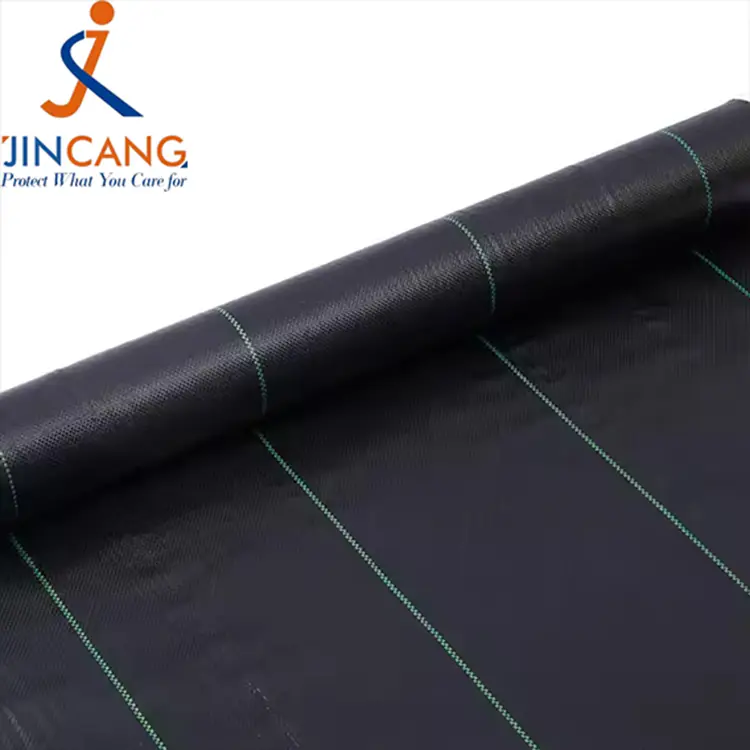

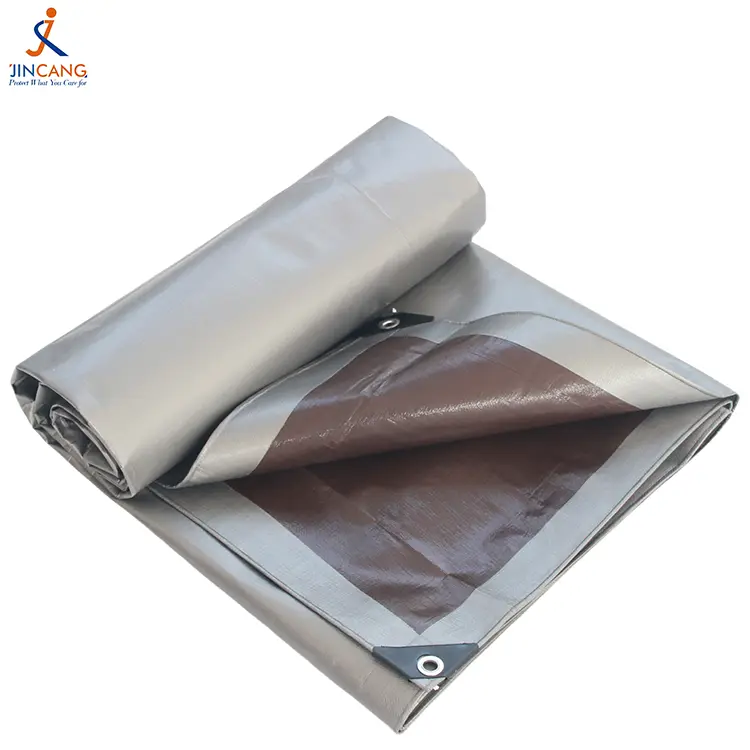

A tarpaulin used for cargo, more commonly called a tarp, is a strong and flexible sheet that is way too long and wide and is used for covering and protecting goods or materials during their transportation or storage. Mostly manufactured from heavy-duty materials like polyethylene, canvas, or vinyl, these tarps are made in a way that they can bear tough environmental conditions including rain, wind, and UV exposure. Cargo tarpaulins are crucial for the safety of the goods during transportation, thus helping to avoid damage. Nowadays, tarps are often equipped with reinforced edges, grommets, and water repellent finishes, which then allowed the tarp to be used over various kinds of loads without any difficulty of falling off and very fastened. Their function can also be seen in many different sectors such as logistics, agriculture, and construction. The value of modern tarps as means of protecting cargo against changes of weather or other causes thus becomes quite clear.

Benefits of Using Tarpaulins for Cargo Protection

When it comes to the storage of cargo with tarpaulins, their usage has many benefits which are practical and generous, also different industries can find them very useful. They are able to keep the weather at its best, to protect the goods from rain, snow, UV rays, and dust, and so they make sure that the products stay most of the time untouched and safe while they are being transported. Besides, the new tarps are not only very tough but also very durable and almost always made of a polyethylene or PVC base that will not tear or wear in normal usage and handling. Moreover, the fabrics of these tarps are so light and their structure so strong that while they protect, they also save a lot of time and effort during the loading and unloading process. Customization is another benefit of many of the tarp varieties, as the materials come in different sizes, thicknesses, and may have special characteristics like heat-sealed edges, and they can even be fire retardant to adapt to the specific needs of the cargo. Such a wide range of availability not only minimizes the loss of goods but also the efficiency, safety, and cost-effectiveness of the supply-chain activities.

Common Materials Used in Cargo Tarpaulins

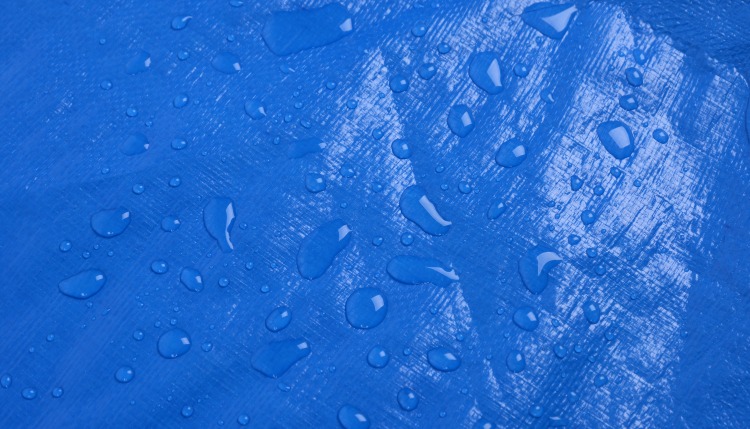

Different materials are used to make cargo tarpaulins, each being chosen according to its strength and flexibility and that it is the right one for specific applications. For instance, polyethylene (PE) is one of the materials that is most commonly used because of its lightness and toughness. Now, a PE tarpaulin, as it is called, is resistant to water and UV radiation, plus it is not expensive, thus, it is the best choice for protecting things generally.

Another popular option is polyvinyl chloride (PVC), a heavier and more durable material often chosen for demanding tasks. PVC tarps are highly tear-resistant, capable of withstanding harsh weather conditions, and customizable with features like fire retardance or anti-static coatings, which are advantageous in specialized industries.

Canvas, a natural, breathable material often made from cotton or polyester blends, is suited for applications requiring reliable but softer coverage. It offers good moisture resistance (when treated) and is often preferred for transporting goods that require proper airflow.

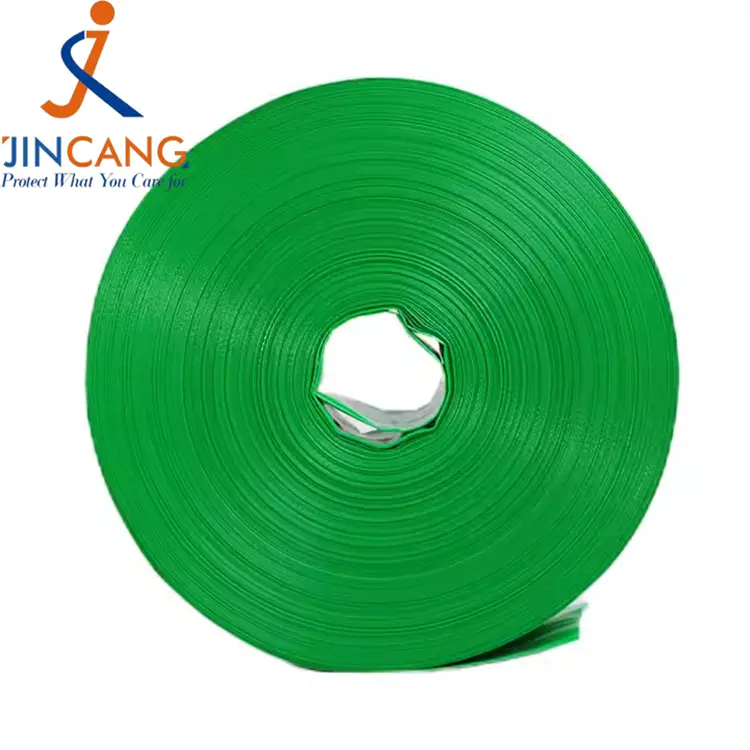

For additional strength and extended service life, some tarpaulins incorporate materials like nylon-reinforced fabrics or hybrid composites, combining synthetic and natural elements. These advanced materials ensure enhanced protection without compromising weight and handling efficiency.

By utilizing these materials, cargo tarpaulin manufacturers cater to a wide spectrum of logistics needs, from standard freight to highly specialized cargo.

Factors to Consider When Choosing a Cargo Tarpaulin

Durability: How to Assess the Strength of a Tarpaulin

Durability for tarpaulin used for cargo must be viewed properly by looking at the materials, the quality of construction and the environmental conditions. High-quality tarpaulins are mainly made from fabrics that are reinforced such as high-density polyethylene (HDPE) or PVC-coated polyester which greatly resist tearing and puncturing in the best way possible. Plus one should not forget to see the ones having multiple layers or those being coated in such a way that they are strong yet flexible.

A different material aspect is the significant cause of electrical resistance, which can eventually weaken some substances, making them break down in the end. Sail cloths having the surface UV treated, are the most probable ones to retain their resistance when used in the open air. Also, water, mold, and abrasion resistance are properties that must not fail, especially when the freight is carried in the course of fluctuating or severe climatic conditions. Besides, the double-stitch and heat-sealed edges beside the canvas increase its life by preventing the material from being worn out or leaking.

Please ensure that you make a sound decision by taking into account the ratio of weight to strength of the material since heavier tarpaulins would usually suggest better durability but also may affect the handling efficiency. Also, going over the tensile strength and load capacity markings of the maker affords you another way to evaluate the tarpaulin’s ability to deal with heavy use and long time. It is important that you buy a durable and good-quality tarpaulin as it means to a great extent that you save money in the long run by reducing the costs of replacing and maintaining.

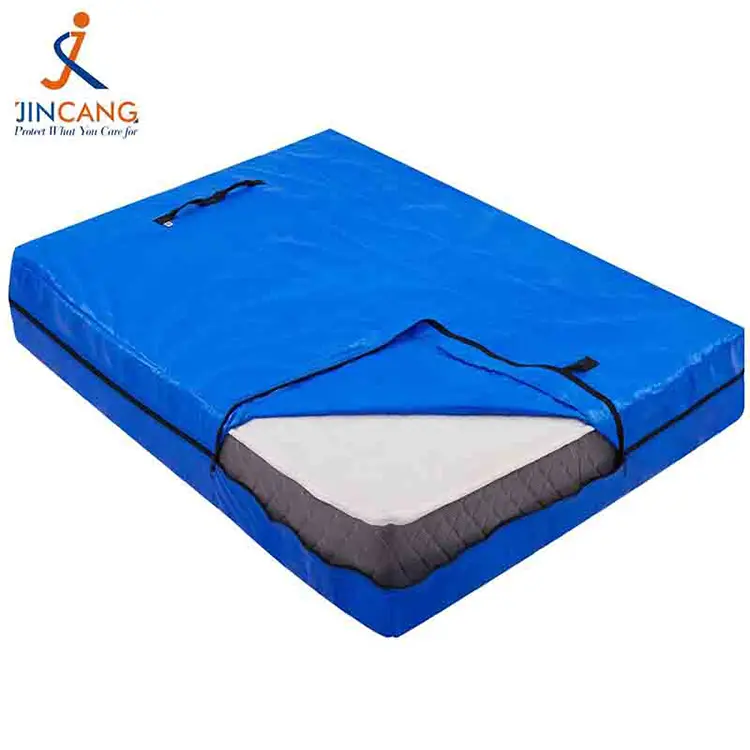

Size and Fit: Choosing the Right Dimensions for Your Cargo

Picking up the suitable size and fit for your tarpaulin is very important, and it guarantees that your cargo is protected and covered effectively. First, measure accurately the dimensions of the cargo and give some extra space for overhang if needed. It is very important to prepare for situations where cargo might move or become settled while being transported due to a total of shifts and thus needing more material to be present and cover securely. It is better to have a tarpaulin that is a little bit larger than the measured area so that these factors are taken care of and at the same time providing a good fit that is also very resistant to wind and will cause less wear. Also, take note of the different types of fastening mechanisms like grommets and straps which help in making the cover tight and reliable. Tarpaulins of the correct size not only protect the cargo from the elements but also help in minimizing losses and maintenance costs during transportation through attaining the desired stability of the load.

Weather Resistance: Protecting Your Cargo from the Elements

In case you want to protect your cargo, the feature of resistance to harsh weather conditions is the most important one when it comes to the selection of a tarpaulin. When polyethylene or vinyl, those are high-quality materials, are used, they have the ability to repel water more effectively; thus, it will not leak and your cargo will be protected from rain. Besides, the application of UV-resistant coatings plays a vital role in shielding your stuff from the adverse effects of sun rays, which can cause fading or the loss of strength of the material. On the other hand, in windy areas, tarpaulin edges that are strengthened and have extra tie-down points are the factors of the stability that the whole cargo’s safety is reduced and there is a lesser chance of the cargo being torn or the tarpaulin being displaced. If one would take the above-mentioned features, he or she will not only have elite status of the cargo integrity in the face of any kind of environmental problem that may arise but also he or she will minimize the risks related to transport delays and losses.

Installation and Maintenance of Cargo Tarpaulins

How to Properly Install a Cargo Tarpaulin

Installing a cargo tarpaulin correctly is crucial to ensuring the safety and protection of goods during transit. Follow these steps for proper installation:

1. Prepare the Cargo Area

Ensure the cargo is neatly arranged and securely fastened. Uneven or loosely

packed items can create pressure points that may damage the tarpaulin or leave

parts of the load exposed.

2. Choose the Right Tarpaulin Size

Select a tarpaulin that fully covers the cargo, with additional material for

securing it properly. Double-check dimensions to account for overhangs and

tie-down requirements.

3. Position the Tarpaulin

Lay the tarpaulin over the cargo evenly, making sure it drapes uniformly on all

sides. Avoid pulling the material too tight, as this may stress the tarpaulin

fabric and compromise its durability.

4. Secure the Sides

Using appropriate tie-down points such as D-rings, bungee cords, or ratchet

straps, secure the edges of the tarpaulin to the vehicle. Begin with the

corners, ensuring they are tightly fastened to prevent slipping or flapping

during transit.

5. Reinforce Key Areas

For areas prone to wind stress, such as corners and edges, consider using

additional fasteners or reinforced straps. If the tarpaulin includes built-in

reinforced patches, align these with pressure points for added strength.

6. Inspect the Installation

Perform a thorough check of the tarpaulin to ensure all tie-downs are secure,

and there are no loose sections that could become potential hazards. Adjust as

needed to eliminate slack or over-tensioning.

7. Regular Maintenance During Transit

Periodically inspect the tarpaulin throughout the journey. Check for signs of

wear, loosening, or damage caused by shifting cargo or environmental factors.

Address issues immediately to maintain cargo protection.

Proper installation not only safeguards your cargo but also improves aerodynamic efficiency during transportation, helping to optimize fuel consumption and reduce overall transportation costs. Adhering to these steps ensures the integrity of both the tarpaulin and the goods it covers.

Maintenance Tips for Longevity of Your Tarpaulin

To keep your tarpaulin strong and supportive all year round, it is very crucial to stick to the consistent maintenance practices. In that case, start with cleaning the tarpaulin weekly with a soft soap and water to take off the dirt, grease, and pollutants which can break the material down. Don’t use any strong chemicals or instruments that are too rough, because all these can make the fabric weak or the protective layers lose its effect. However, if you’ve done the cleaning right, make sure that the tarpaulin is completely dried afterward so that mold and mildew are not allowed to grow.

Examine your canvas for evidence of wear and tear like rips, unraveling sides, or weakened grommets. Repair small problems at once using repair patches or adhesive designed for tarpaulin repair. Think about a professional repair service to recondition the fabric in order to fix major damages or persistent problems.

Proper storage is also a very important factor influencing the life of a tarpaulin. Always keep it in a dry, cold place out of direct sunlight, as the latter can slowly and surely deteriorate and discolour your tarp. Rolling tarpaulin is better than folding because the latter may cause the fabric to crack due to creases.

Lastly, ensure your tarpaulin is securely installed during use to minimize exposure to unnecessary stress and environmental damage. Long-term care not only protects your tarpaulin investment but also maintains its efficiency in safeguarding cargo.

Repairing Common Issues with Tarpaulins

Gradually, the repeated use and the harsh conditions can make the tarpaulins frail. However, it is possible to make them last longer and keep their functionality if you deal with the problems quickly. In the case of the smallest openings or tears, you can employ a proprietary adhesive tape of a good brand that is produced specifically for the tarpaulin materials. But first, see that the area of the damage is not only clean but also dry in order to have a good and durable bond. For much larger damage, thread the tears up with a strong nylon thread and then put a patch over it that is made of the same material to further secure the weak area.

Grommet damage is a very frequent problem. It can weaken the hold of the tarpaulin. Take care of it by utilizing a grommet repair kit to substitute the broken or missing ones, and make sure that they are appropriately aligned in order not to add up stress on the fabric. If moisture retention is the reason mildew or mold is starting to appear, then cleaning the surface is the way to go, with mild soap and water, and then dried thoroughly to prevent further growth. It is of utmost importance that you carry out regular inspections and do the necessary repair works at the right time in order to keep the tarpaulin in good working condition for a longer time.

Testing and Quality Assurance for Cargo Tarpaulins

Importance of Testing Tarpaulins for Cargo Applications

It is important to carry out a rigorous testing of the tarpaulins that are made for cargo applications so as to make sure they can meet the requirements of different transportation situations. The tests that will be done are for the durability factors, and also for the weather resistance and load-bearing capacity. These are very critical tests because they can help avoid material failures that could compromise the goods’ safety. During testing, the usual procedure includes checking the strength of the fabric, the seam’s condition, and the materials’ resistance to UV rays, rains, and extreme temperatures.

Moreover, testing is critical in that it guarantees that compliance is met with industry standards like tear strength and water resistance, which are very important for maintaining the cargo in a good condition throughout the journey. The changes in the material sector, like the fortification of polymers and the utilization of new coatings, have also culminated in more durable options being introduced; however, the quality assurance process still relies on continuous checks. The firms that institute appropriate testing procedures not only reduce risks but also realize the efficacy of the operational process as the clients get more confident in their cargo handling.

Understanding Code Coverage in Tarpaulin Quality Testing

Tarpaulin quality testing is a process that heavily relies on the code coverage metric to offer practical and easy to measure means of how deep the testing was done on the material. It is the degree to which the testing design has probed or “covered” the possible weaknesses of the tarpaulin, like its wear resistance, wetness barrier, durability, and UV rays shield. High code coverage means that the testing goes through a broad variety of conditions and strain points so that very few defects are left undetected.

A comprehensive code coverage strategy that is well-thought-out will contain the most recent testing advancements like automated durability tests and environmental simulations that mirror real-world usage. For example, a tarp’s waterproofing capability can be assessed by running high-pressure water penetration tests, and the sun’s accelerating effect on different materials can be measured in terms of their resistance via the use of UV accelerators. On the whole, through the merging of these techniques, the accuracy and reliability of the testing process are duly enhanced.

In addition, the use of sophisticated data monitoring systems allows for quick analysis of findings and thus gives the opportunity for teams to discover patterns and adjust activities in a very proactive way. When the code is thoroughly covered, the manufacturers not only get good performance metrics for the tarpaulin but also get the added assurance of being in compliance with the very strict industrial standards, thereby, giving them an edge in their market.

Best Practices for Assessing Tarpaulin Performance

In the current competitive market, it is vital to integrate modern evaluation techniques with traditional methods to accomplish the right performance evaluation of tarpaulins. It is the involvement of material stress analysis simulations and advanced durability testing tools that gives us a better picture of the tarpaulin’s stress-bearing abilities in diverse conditions. Setting the evaluation conditions that the tarpaulin can be static at is the possible way for the environmental testing chambers to be useful. That means the manufacturers can reproduce the adverse weather conditions on the tarpaulin during the test, such as heavy rain, UV exposure, and high winds, and quantify the level of stress endured by the material under such external and prolonged conditions. Besides that, the use of automated inspection systems directs consistent quality control, thereby helping in spotting weaknesses and defects at the manufacturing stage. Furthermore, feedback from these systems, along with that from long-term field tests, presents the manufacturers with actionable intelligence to streamline processes. Consequently, the use of cutting-edge analytic methods along with stringent testing routines can not only elevate the tarpaulin’s overall performance, reliability, and market prices significantly but also help manufactures keep up with changing industry standards.

Integrating Technology with Cargo Tarpaulins

How Jincang and Crate Can Enhance Tarpaulin Management

In my opinion, the usage of Jincang and CrateDB is the best option in the case of tarpaulin management systems to have performance metrics under control. Jincang is the most effective and efficient when it comes to managing difficult processes because it contains various versions with various implementations also having a huge range of hardware support. Its free for all characteristic allows developers and users to enjoy the freedom of enhancing system functionalities and also making sure that the software fits tarpaulin manufacturers and logistics firms requirements specifically. Jincang is a modular system, so the tarpaulin team can select only the required applications but still have a smooth production-deployment process.

CrateDB works with this configuration; it behaves like a very fast, distributed SQL server that is good at managing an enormous quantity of time-series data that gets generated during the process of tarpaulin management. Crate is very good at managing real-time data analytics, which is a very important point in monitoring the tarpaulin’s durability, weather resistance, or load performance in real-time environments. This means that manufacturers, like ourselves, can effectively continuously monitor and analyze the quality of our products, detect potential trouble spots early, and identify trends that cut down on material and product optimization. Through the use of Crate’s scalability, we, as well, can be sure that our system can grow with the data without losing performance.

Jincang and Crate together boost the decision-making process of businesses by giving detectable insights through the data visualization and analysis tools of great efficiency. The double also reduces money spending significantly, considering it is the purpose of both the solutions for the user to afford and adjust everything. This combination creates for manufacturers and the logistics team a system where they can easily comply with the sector’s requirements and at the same time increase their operational efficiency and thus the customer satisfaction through a tech-savvy strategy that does not underestimate the future.

Utilizing CI for Efficient Tarpaulin Deployment

When it comes to the efficient deployment of tarpaulins, I use CI (Continuous Improvement) methods to make the process smooth and the result better. CI means little, gradual changes that, when done repeatedly, bring about significant improvements, and this is most useful in the case of tarpaulin deployment. The use of the current workflow analysis method, bottlenecks identification, and the use of the practice of data-driven insights enables us to ensure effectively utilized resources like manpower and tools. For instance, the preparedness, transportation, or installation steps can be analyzed and errors can be identified and solved one by one through process mapping, and feedback loops.

Technology and CI integration is one of the most important areas where I put my efforts. I can achieve an excellent level of precision in logistics planning by using cutting-edge tools such as GPS tracking and inventory management tools, which allow me to detail where the materials are to be supplied to and ensure they are there at the right time. Moreover, sensor-based monitoring will give minute-by-minute updates on the deployment progress, which will decrease the waiting time and enhance the collaboration between the teams. Not to mention that I keep evaluating the process for future deployments and for that, I employ various metrics like setup time, material usage rates, and quality assessments.

Through CI principles, it’s not just the speed and accuracy that I am working on improving; I am also making sure that the durability and performance of the tarpaulins deployed are of the highest standard or even better. The integrated option of going for the iterative upgrading along with the use of the latest technology no doubt is a great help to the realization of both efficiency fists, the first bright one, and the second dark one.

Future Trends in Cargo Tarpaulin Technology

Looking at the future, the industry behind cargo tarpaulins appears to be non-stop innovating. Day in, day out there are new technologies which are made to progress the endurability, usability, and eco-friendliness of the tarpaulins. Out of the very best, we find the making of the tarpaulins combined with smart technology and the use of IoT sensors, thus releasing no room for doubt that these intelligent tarpaulins would be the future of the market. These sensors keep an eye on the real-time environmental conditions like the temperature, humidity, and pressure, making sure they are safe throughout the journey for the sensitive loads. The information obtained does not only help to optimize the operations but also gives an understanding of the performance of tarpaulins in different conditions, thus facilitating more informed material and design changes.

Eco-friendliness and sustainability are gradually becoming a common trend and remarry in terms of material. Due to the world’s devotion to eco-consciousness and the desire to decrease the number of pollutants produced, manufacturers are looking into the use of biodegradable or recyclable materials instead of the traditional polyethylene and PVC fabrics. The developments in material science have made it possible to come up with extremely tough bio-based polymers and coatings that provide the same sturdiness and weather-resistance qualities minus the environmental harm. It should be noted that this path of change is not only one of the most widely recognized ones worldwide in terms of sustainability, but it also is perceived as very important for businesses considering greener practices in their supply lines.

It’s been long awaited for, but it’s here now! With the advent of individually-made and changeable tent designs, the whole cargo industry is making use of such to deal with the most flexible and versatile cargos. Three-dimensional printing and precision manufacturing have been the pioneers, in providing custom-fit tarpaulins, and thus, guaranteeing better coverage and lower wearing. In addition, with the use of AI technology in the maintenance field, these tarpaulin designs are just going to be seen as the starters of the new era when it comes to cargo protecting that is more efficient, flexible, and advanced technologically.

Related News

- Is Light Duty PE Tarpaulin the Most Cost-Effective Protective Covering for Everyday Use?

- Lamination Tarp: Enhances Tarp Durability 2026

- PE tarpaulin : Waterproof vs. Water-Resistant: Understanding the Exact Difference

- What Are the Common Applications of PE Tarpaulins in Transportation

- 8'x10' 110GSM Brown Green PE Tarpaulin for Cover Protection

- What are the performance advantages of PE Tarpaulin Roll?

Leave me a message