- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What factors affect the service life of PE tarpaulin?

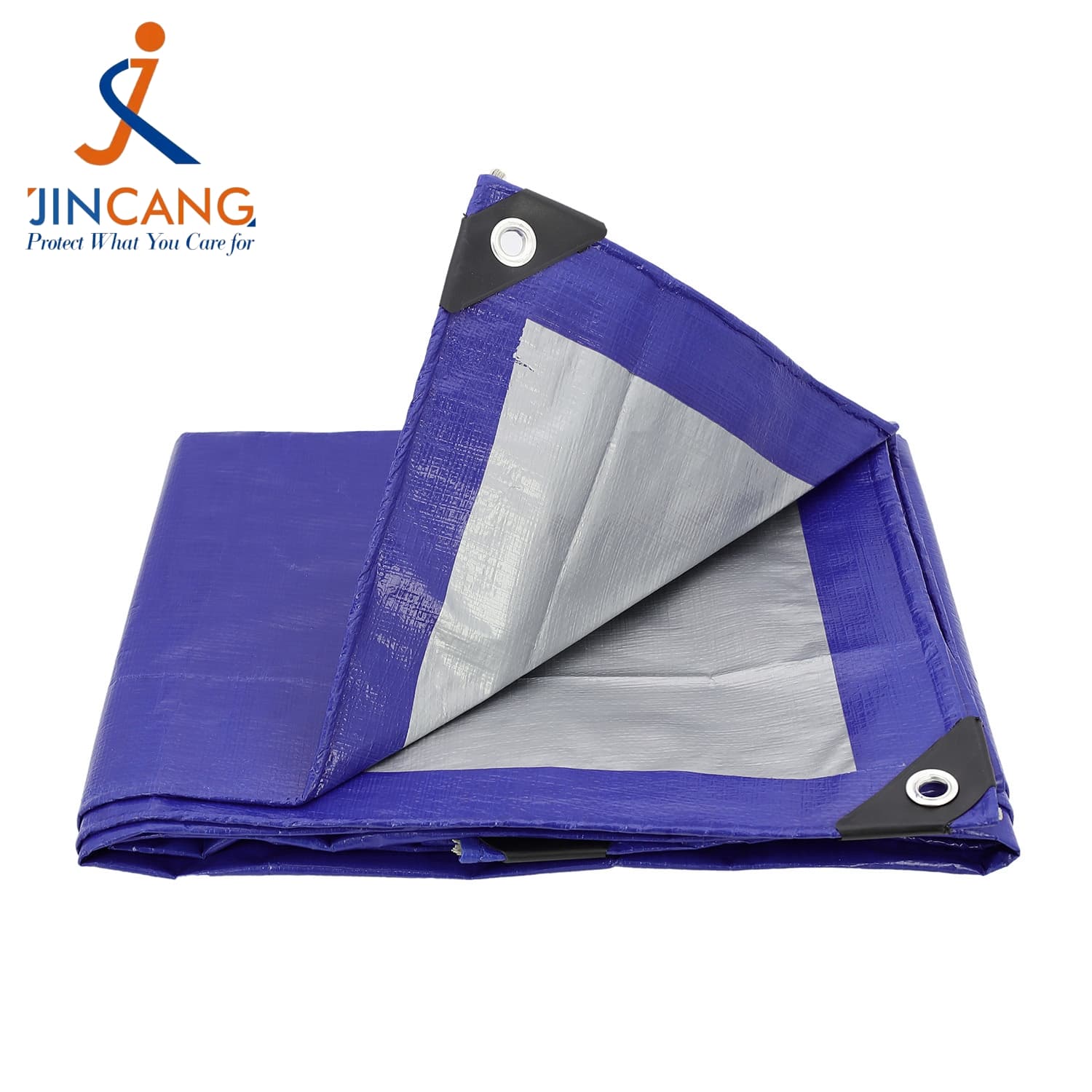

As an economical, practical and widely used protective material, PE tarpaulin plays an important role in construction sites, agriculture, logistics and transportation, outdoor activities and other scenes. One of the most concerned issues for many users when purchasing is: How long can PE tarpaulin be used? In fact, its service life is not static, but is affected by many factors. This article will take you to understand the key factors affecting the durability of PE tarpaulin, helping you use it longer and more valuable.

1. The quality of raw materials is the basis

The core material of PE tarpaulin is polyethylene, and the purity and ratio of raw materials directly determine the overall performance of the tarpaulin. In order to reduce costs, some manufacturers will add a large amount of recycled materials or inferior fillers in production. Although this kind of tarpaulin is cheap, it has poor strength, is easy to age, and has weak sun resistance, so its service life is naturally discounted. On the contrary, tarpaulins produced with high-density polyethylene raw materials are not only tough and tensile, but also more weather-resistant and have a longer service life.

2. Weight and thickness affect durability

The thickness of PE tarpaulins is usually measured by "weight". Simply put, the higher the weight, the thicker the tarpaulin and the stronger its tear resistance. If it is just a temporary cover, generally products with a lighter weight can meet the needs. But if it is used outdoors for a long time, especially in windy, rainy and sunny environments, it is recommended to choose products with a weight of more than 150 grams to ensure better durability and stability.

3. The use environment determines the "lifespan"

Where the PE tarpaulin is used will also directly affect its lifespan. When used indoors or under a sunshade, the tarpaulin will basically not be affected by wind and rain, and it will be fine for several years. But if it is exposed to the sun in an outdoor environment, the tarpaulin will gradually become brittle and lose its elasticity if it is exposed to ultraviolet rays for a long time. Therefore, if the tarpaulin is used in a harsh environment, it is recommended to choose products with anti-UV treatment or lamination technology, which are more sun-resistant and aging-resistant.

4. Whether the use method is appropriate is also critical

The correct use method can effectively extend the use time of PE tarpaulins. For example, when fixing the tarpaulin, if it is pulled excessively or unevenly, it is easy to cause the corners to break or tear. In addition, it is best to avoid direct contact with sharp objects or high-temperature equipment during construction to avoid damaging the surface of the tarpaulin. Cleaning up dust and accumulated water in time after use, and properly folding and storing after drying can also effectively prevent problems such as mold and aging.

5. Maintenance and storage habits affect the effect of reuse

Many users will reuse PE tarpaulins, so maintenance is particularly important at this time. If the tarpaulin is randomly stacked, uncleaned, and not moisture-proof after use, even the best quality materials are easily damaged. It is recommended to check for damage, clean stains, dry moisture, and then fold and store in a cool and dry place after each use. A small good habit may extend its service life by one or two times.

6. Process details determine the use experience

In addition to materials and thickness, process details such as edge stitching, buttonhole reinforcement, and edge pressing of PE tarpaulins will also affect the actual use effect. A tarpaulin with firm corners, neat seams and durable holes is less likely to be damaged in wind and rain, and can be used repeatedly. Choosing products from manufacturers with mature technology and solid workmanship is a key link to ensure service life.

In general, there is no uniform standard for the service life of PE tarpaulin, but it is determined by a variety of factors such as raw materials, thickness, use environment, and maintenance methods. If you want to use it longer and more safely, you should not only look at the price when purchasing, but also pay attention to the "inner qualities" such as material, weight, and craftsmanship.

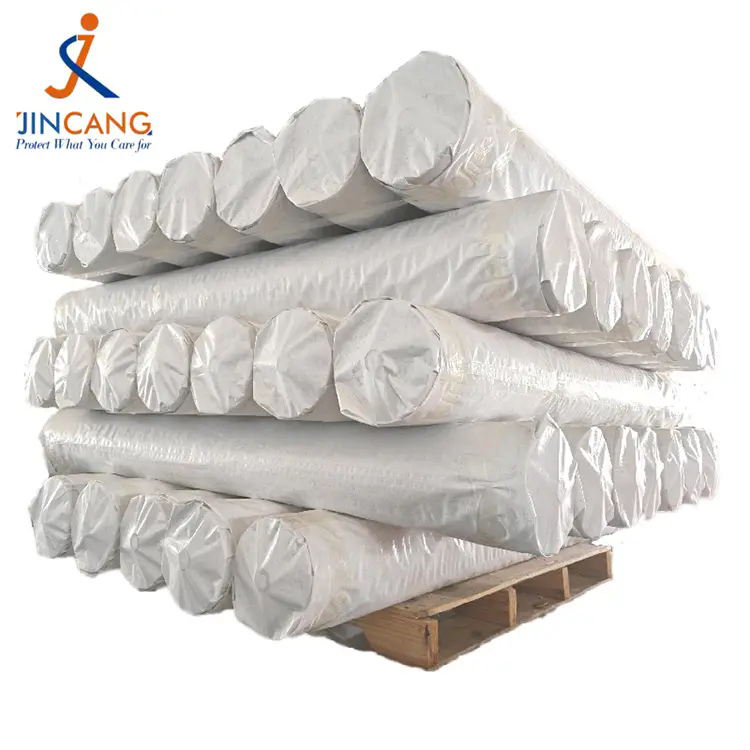

We focus on the production of various types of PE tarpaulins, supporting a variety of thicknesses, colors, specifications and functional customization, and our products are widely used in multiple industries. If you have higher requirements for product durability, please contact us, we will recommend a more suitable solution for you, so that every tarpaulin is worth the money.

Related News

- Lamination Tarp: Enhances Tarp Durability 2026

- PE tarpaulin : Waterproof vs. Water-Resistant: Understanding the Exact Difference

- How to Choose the Best Cargo Tarpaulin for Maximum Protection and Durability

- What Are the Common Applications of PE Tarpaulins in Transportation

- 8'x10' 110GSM Brown Green PE Tarpaulin for Cover Protection

- What are the performance advantages of PE Tarpaulin Roll?

Leave me a message

New Products