- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Is The Raw Material Of Tarpaulin?

Tarpaulin is a versatile material widely used in outdoor covering, rain and sun protection, cargo transportation, construction and other fields. Its durability, waterproofness and tear resistance make it a common choice in many industries. To understand the performance of tarpaulin, we first need to talk about its raw materials. So, what are the raw materials of tarpaulin? What are the differences in the selection of raw materials for different types of tarpaulins? This article will reveal the core composition behind this common product from a professional perspective.

At present, there are three main types of tarpaulin raw materials that are most widely used in the market: polyethylene (PE), polyvinyl chloride (PVC) and canvas (usually a combination of cotton or polyester and coating materials). Different materials determine the purpose, performance and durability of tarpaulin.

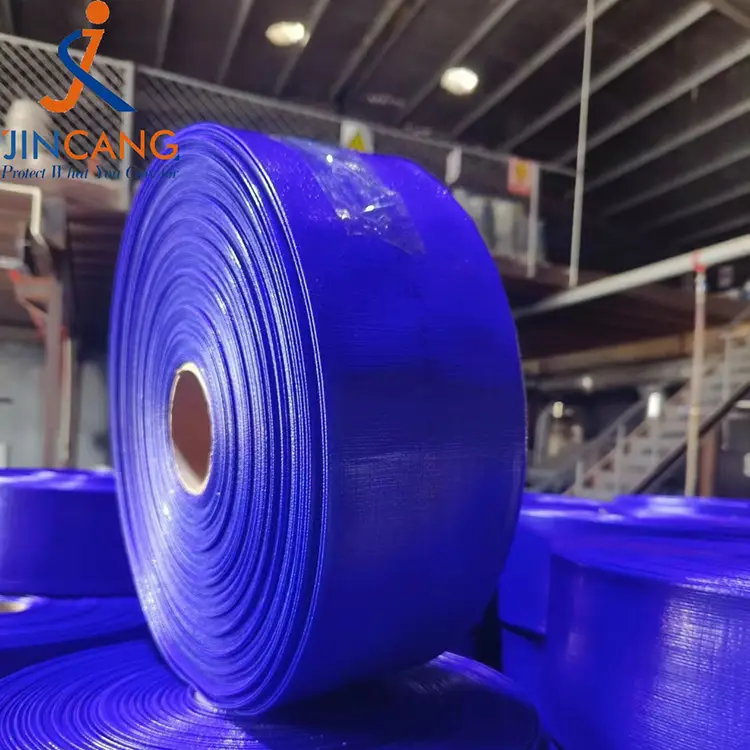

First is polyethylene, which is what we often call PE tarpaulin. This type of tarpaulin uses high-density polyethylene as the main raw material, and after weaving, it is covered with a layer of low-density polyethylene film to form a finished product with good waterproofness and lightness. PE tarpaulin is relatively affordable, light in weight and flexible, and is often used in temporary covering, cargo packaging, simple building roofs and other scenes. However, due to its relatively general anti-aging ability, it is more suitable for short-term or medium-intensity use needs.

The next type of tarpaulin is polyvinyl chloride, or PVC tarpaulin. The foundation of this kind of product is high-strength polyester fabric that has been covered with a layer of polyvinyl chloride material and then pressed at a high temperature. In addition to its exceptional waterproof, sun-proof, and flame-retardant qualities, PVC tarpaulin has a very high resilience to weather, tensile stress, and wear. Truck tarpaulins, technical enclosures, temporary warehouses, and other high-intensity industrial applications can all benefit from its use. It is a premium tarpaulin material, and its service life is also longer than that of PE tarpaulin.

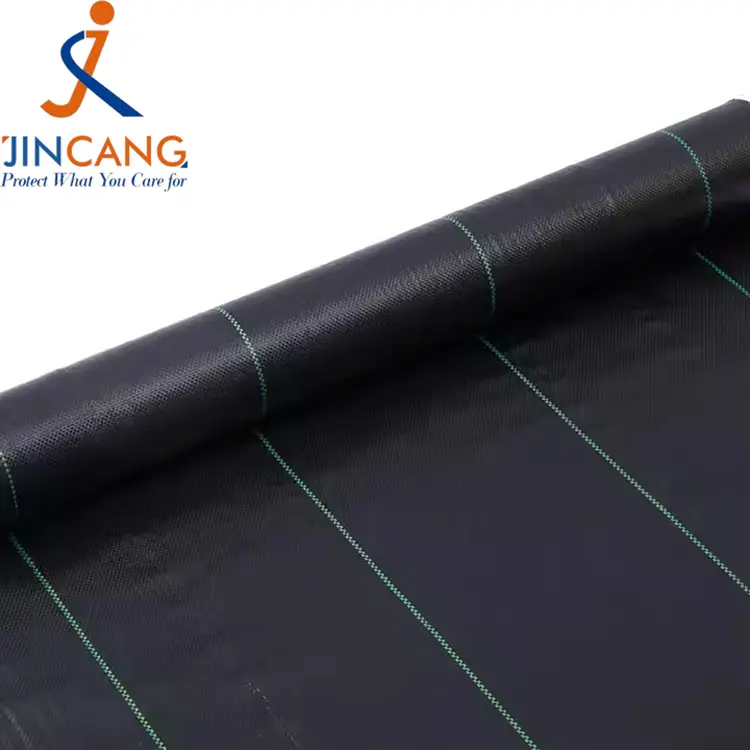

Another traditional tarpaulin material is canvas, which is mainly woven from cotton or polyester-cotton yarn and becomes a basic tarpaulin after waterproof treatment. This type of tarpaulin has a thick texture and good breathability, and is widely used in military, camping, tents, field operations and other environments. Although it is slightly inferior to synthetic materials in terms of waterproof ability and mildew resistance, its natural ingredients have certain advantages in environmental protection and degradability.

Modern tarpaulin production may also use a range of additives and composite techniques, such as UV inhibitors, mildew inhibitors, flame retardants, etc., in addition to the three primary raw material categories mentioned above. By adding these components, tarpaulins' performance may be optimized based on usage conditions, satisfying the many customers' individual needs.

In general, the performance of tarpaulins is directly related to their raw materials. PE tarpaulins are light and economical, suitable for daily short-term use; PVC tarpaulins are durable and suitable for high-frequency outdoor operations; and canvas is closer to tradition, emphasizing breathability and natural texture. When choosing tarpaulin products, companies should combine the actual use environment, budget and life requirements to scientifically select the appropriate material type to achieve better use effect and cost-effectiveness. If you have more questions about different tarpaulin materials, please contact us, we will provide you with professional selection suggestions and technical support.

Related News

- Lamination Tarp: Enhances Tarp Durability 2026

- PE tarpaulin : Waterproof vs. Water-Resistant: Understanding the Exact Difference

- How to Choose the Best Cargo Tarpaulin for Maximum Protection and Durability

- What Are the Common Applications of PE Tarpaulins in Transportation

- 8'x10' 110GSM Brown Green PE Tarpaulin for Cover Protection

- What are the performance advantages of PE Tarpaulin Roll?

Leave me a message